About Us

About

Mr. Wang’s companies cover production of a wide spectrum of items from furniture, plywood factory, fructose and glucose production and more. In his spare time Mr. Wang enjoy investing in ventures that will help provide future prospects for the youth of Taiwan.

In the downstream sector, TBL produces plywood with high quality with global market . With a capacity of 36,000 m3 per years and workforce approximately 200, TBL continues to develop potential international markets e.g. American, European countries, Middle East countries and son on. For the purpose of maintain the quality of our products, TBL proves commitment by VLK certificate from the Government of the republic Indonesia, however our products have high demand in the United States of America, TBL is awarded CARB-certified that the standard is now one of the most stringent standards for formaldehyde emission from composite wood products, and it requires factories to strictly supervise the production process according to the regulations.

Production Process

-

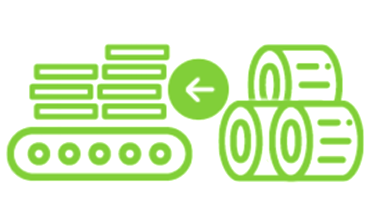

Veneer rotary peeling

Veneer rotary peeling Veneer rotary peeling lathe is an industrial machine that is used to peel thin sheets of wood veneer from a log.

-

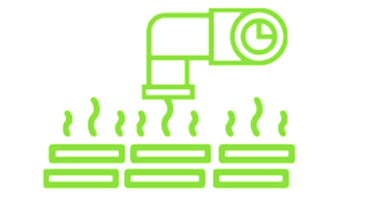

Veneer roller dryer

PT. Timberland is set to build Indonesia’s biggest veneer roller dryer , boasting a 40 meter to dry. Veneer’s humidity is very important in controlling quality.

-

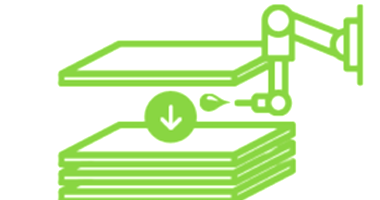

Glue blending and spreader

Using glue spreader which can precise control glue usage to apply evenly.

-

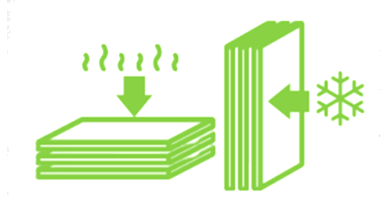

Cold press and Hot press

PT. Timberland use 1200 tons hot press that is make sure glue coating and flatness.

-

Cutting

Using automatic cutting machine, it can precise cut the size and right-angle.

-

Quality control

Batch and batch inspection coating strength and formaldehyde content before packing.